When you are looking to join two pipelines or practically any piece of metal, you need to use welding. But what type of welding is used for gas pipelines? Is it live gas line welding or something else? Let us find out.

Live Gas Line Welding

Live gas line welding, also known as hot work on live pipelines, is a specialized process whereby welding operations are performed on pipelines carrying gas under pressure. The major welding processes adapted for the live gas lines include Shielded Metal Arc Welding (SMAW) and Gas Tungsten Arc Welding (GTAW).

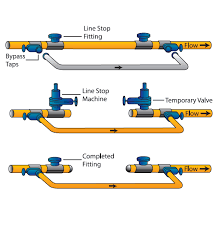

Hot Tap Welding

Hot tap welding is a specific welding type applied during hot tapping. The welding is done on top of the branch fitting added in, and a valve is set inside to control the flow. The most common welding method used is the SMAW because of the versatility and field reliability of the process.

Pipeline Welding Test

A pipeline welding test is critical for checking the quality and safety of welds done on gas pipelines. To ascertain weld integrity and conformance to industry practices, tests for the pipeline weld are conducted before, during, and after the welding process. The standard tests include radiographic testing, ultrasonic testing, magnetic particle testing, and many others. These tests show defects, for example, cracks, porosity, and incomplete fusion, that may weaken the pipeline’s structure.

Fitting Pipe for Welding

Proper fitting pipe for welding in gas pipelines is paramount. Fitting a pipe consists of preparing the ends of pipes, aligning them with perfection, and holding them firmly in place before welding starts. Mostly, pipe ends are bevelled to form a groove that usually resembles a ‘V.’ Clamps and fixtures hold the pipes in place while welding to maintain proper alignment during the process. The joint is supposed to be free of all contaminants such that the weld has no defects. Exact fitting and alignment will help avoid gaps, which can further help facilitate an even weld penetration for it to hold well, be strong, and be durable so that it can resist the pressures and stresses of gas transportation.

Special welding techniques and rigid testing will be able to ensure the proper safety and integrity of the joints. Live gas line welding, hot tap welding, rigorous pipeline welding tests, and meticulous fitting of pipes are also critical components of this process. If these industry standards are followed, you can work on the existing and new gas pipeline systems safely and efficiently with minimized risk to the public, environment, and infrastructure. At Equip Up, we specialize in hot tapping welding applications. Contact us today for your hot tap and stopple fitting and equipment.