Hot Tapping is a method that establishes safety and reliability in industrial pipelines. It ensures a controlled access point without requiring completely shutting down the system. The Hot Tapping procedure involves drilling a hole into the live system and then attaching a tap or nozzle as per the requirement. This is how new connections on the pipeline can be made. The hot tapping method often brings up another term – that is Line Stopping. Both are somewhat the same, but there is a slight difference between the two.

What Is Hot Tapping And Line Stopping Procedure?

Hot Tapping and Line Stopping are two different methods of pipeline maintenance. Both of them are required for the improvement of material flow without experiencing downtime or related interruptions.

- The procedure of Hot Tapping is suitable when you want to conduct maintenance work in the pipeline that is still in service.

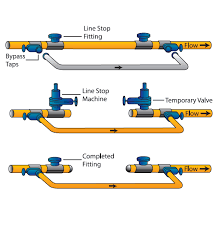

- On the contrary, Line Stopping is something that temporarily stops the flow of the material inside the pipe. A plug or seal is inserted in the line.

Hot Tapping Procedure: Advantages & Disadvantages

ADVANTAGES

- The Least of Disruptions

This is one of the main advantages of the hot tapping procedure. Repair works or new connections can be easily established on the main line without shutting down the system. - Cost-Effective

Shutdown and complete isolation can be expensive. Therefore, by eliminating these operations, it is possible to minimise the cost of repair work or new connections. Also, reduced environmental impact due to minimised emissions and loss of product is a factor. - Adaptability & Versatility

Hot Tapping is suitable for a wide range of materials, pipes, and pressures. The method is applicable for both offshore and onshore. Therefore, it can be used for a number of applications in diverse situations.

DISADVANTAGES

Hot Tapping in Piping is Not Exactly Suitable for Every Condition

Hot Tapping in piping does not suit some conditions. For example, when the temperature is too high or low, extremely corroded pipes, or the material of the pipeline is not compatible. In these cases, alternative methods like Line Stopping are required.

Safety Issues

Hot Tapping certainly ensures safety to the overall pipeline, however, the process is itself a bit risky. Without proper expertise and precision, various complications can arise. These are:

- Weakened pipeline

- Formation of Leaks

- Explosion of Pipeline (rare case)

Hot Tapping Saddles

It is pivotal to buy hot tapping saddles that are compliant with the applicable codes like ASME B31.3 and DOT. Choose a Tecpesa-authorised distributor to ensure safety through the products. Threaded hot tapping saddles are available to create branches in the pipeline. They can be used in pressurised supply networks to avoid loss. The best part is, these saddles are equipped with a rotary shut-off blade that immediately cuts off the flow inside once the branch has been drilled inside.

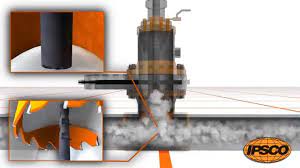

Hot Tapping Machine For Pipeline

Tapping machines for pipelines are available in various sizes. The saddles persist for about 15 to 20 years if proper and routine maintenance is provided. They can seamlessly penetrate a vessel or any piping wall. Remember, these tapping machines must be evaluated based on the merit of the job and its related factors.

Hot Tapping machines for pipelines can be employed electrically, hydraulically, pneumatically or manually. To secure your anchoring point and the entire pipeline management, get quality products from Equip Up. According to the required specifications, we provide cut-to-size hot tapping saddles and other products at cost-effective rates.