Worldwide, various types of pipelines carry resources like natural gas and oil, making the uninterrupted flow and integrity of these pipelines crucial. But what if a section of the pipeline needs to be stopped for maintenance or emergency? This is where the stopple fitting, a key tool in our industry, comes into play, ensuring the isolation of the specific part of the pipeline. These fittings are typically installed in petrochemical plants or refineries.

What is a Stopple Fitting used for?

Stopple fitting is used during:

- Temporary line-stop operations

- To create a secure seal

- Maintenance activities

- Pipeline repair works

- Pipeline inspections

- Pipeline additions (Hot Tapping)

- Pipeline Relocation

Hot Tapping and Stopple Fitting in Details

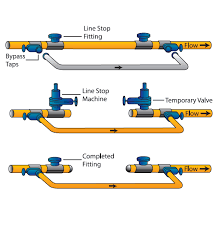

A Stopple Fitting is usually known as a pipe stopper or line stopper. It is specially designed to isolate or block the line temporarily. This is why hot tapping and stopple fitting go hand in hand. These stoppers can isolate the flow in each section of a line, thus sealing off the area without even disrupting the rest of the flow in the system. A pipeline stopple fitting is a specialized entire branch of split tee designed to be used for TDW plugging machines. Several materials are available to suit the existing pipeline and its operational compatibility.

In the 1950s, T.D. Williamson invented the stopple fitting and plugging system, a groundbreaking invention that continues to be one of the most widely used applications for isolating a section of a pipeline. This legacy underscores our work’s impact on the oil and gas industry.

The Working Process of Stopple Plug

A stopple plug or line stopper, while a bit more complicated than usual hot taps, is a simple and efficient tool. The pipe is attached to a fitting, and after it is completed, the valve is closed. The stopple plug is then installed on the pipe. An actuator is used to insert the plugging head inside the pipe. Line stops are beneficial for replacing the fittings, valves, and other equipment. After this, the pressure is then equalized before removing the head. This simplicity and efficiency make it a valuable asset in our operations.

The stopple fitting is equipped with new-age flanges that allow the safe removal of any valve. Several flange designs are available to suit the pipeline’s operations. The flange inserts the plug through the valve and can be securely locked.

What Are The Applications of Pipeline Stopples?

- Pipeline Inspections: A pipeline stopple fitting is used to conduct proper inspections and detect potential threats from leaks and corrosion.

- Product Changeovers: Stopples must change a product equipped with a multi-product pipeline, which is designed to prevent cross-contamination.

- Maintenance and Repairs: Line stoppers can quickly isolate malfunctioned or damaged sections of a pipeline. This allows safe and systematic repair work without entirely shutting down the system.

- Hot Tap: When hot tapping is required for branch connection, a stopple fitting is also used.

Let’s Stopple Plug for Now!

A pipeline stopple plug is a crucial device for almost every energy industry. It ensures safe and continuous transportation of resources throughout the system. The devices are surely indigenous in protecting the environment and ensuring reliability. Human safety is also a matter of stopple plugs contributing to the efficacy of pipeline systems throughout the planet.

At Equip Up, we offer our Tecpesa brand of Hot Tapping and Line stop fittings and equipment suitable for every operation regardless of size. Contact Equip up store for all your hot tapping and stopple equipment and supplies at sales@equipupstore.com or call +1 832-407-1666