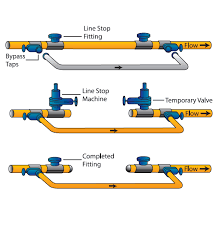

When you are planning and building a pressurized piping system project, you need to choose fittings that you can rely on. Hot tapping is one of the widely used methods to safely tie in a pressurized system using drilling or cutting. In this article, we will look at how you can choose the right hot tap fittings for your piping project.

Choosing the Right Fit and Size for Your Hot Tap Pipe Fittings

When you are out choosing hot tap pipe fittings, it is difficult to overstate the importance of choosing the right size and the right fit for the system. At Equip Up, we stock TECPESA hot tap fittings of up to 48” in size. You can also get larger sizes and pressure ratings, which are available on request.

When it comes to fit, our hot tapping fittings are designed to be used with the following TECPESA Hot Tapping and Pipeline Hot Tapping equipment:

- TBL-182TH

- TBL-242TH

- TBL-302TH

- TBL- 0322

- TBL-0644

- TBL-1106

Determine if Reinforcements are Required for Pipeline Hot Tapping

Another important decision that you need to take while choosing fittings for pipeline hot tapping is whether reinforcements are required or not. Reinforcements give a range of different benefits. For example, reinforcements can provide additional strength to weak points or vulnerable areas of the fittings, preventing them from deforming, cracking, or failing during tapping.

In some cases, reinforcements may be necessary to ensure proper alignment, support, and attachment of the tapping equipment to the fittings. This ensures a smooth and efficient tapping operation.

Our fittings for pipeline hot tapping can be manufactured with a different reinforcement like a Weld-o-let or Pad reinforcements. If you need a ‘size-on-size’ fit between the pipe and the fitting is required, you will need full encirclement reinforcement. If you don’t require any reinforcement, TECPESA manufactures the fitting with a scarfed or flat bottom ending.

Ensure Your Hot Tap Tee Meets the Industry Standards

When your hot tap tee meets the industry standards, you can be sure that it is capable of meeting the desired levels of performance. To ensure that your hot tap tee is equipped to deliver the performance that you need, they come with a welding neck flange RF according to ANSI Class 150, 300, 600, or 900. The fittings are fully compliant with applicable codes, including ASME B31.3 and DOT.

Get the Best-in-Class Hot Tapping Fittings from Equip Up

If you are looking for premium hot tapping fittings, then Equip Up is the right option for you. We offer a wide range of full-branch split tees designed for equipment tie-ins, lateral connections, and line extensions with permanent full-bore valves. You will get a wide variety of colors, dimensions and are fully EQA certified. With our efficient logistic network, you will get the products delivered to you in as little as eight to ten weeks. So, contact Equip Up today and get quality hot tap fittings that deliver the performance you need.