When working on an existing pipeline, there are a few important equipment and fittings that you should know about. One of the most important fittings you should work with is the threaded plug linestop fittings. But before we get into that, let us first understand what a linestop machine is.

What is a Line Stop Machine?

A linestop machine is a piece of equipment used in pipeline maintenance and repair. It temporarily stops the flow of liquids or gases in a pipeline without shutting down the entire system. This is mostly used when shutting down the pipeline would be costly or impractical.

Linestop machines are essential tools for maintaining pipeline integrity and minimizing downtime during maintenance activities. They are used in various industries, including oil and gas, water distribution, and wastewater management.

How Does a Line Stop Machine Work?

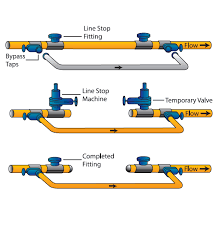

Here’s how a linestop machine works:

- A temporary stopping mechanism, such as a plugging device or a sandwich valve, is inserted into the pipeline through a hot tap.

- Once the stopping mechanism is in place and properly sealed, the flow of the product in the pipeline is halted.

- Maintenance or repair work can then be carried out downstream of the linestop point, while the rest of the pipeline continues to operate as usual.

- After the work is completed, the linestop device is removed, and the flow in the pipeline is restored.

What are Threaded Plug Linestop Fittings?

A Threaded Plug Linestop Fitting is a type of linestop equipment designed to temporarily stop the flow of liquids or gases in a pipeline. This fitting is threaded to allow for a secure and tight connection to the pipeline, ensuring a reliable seal during operation.

Threaded Plug Linestop Fittings are commonly used in various industries, such as oil and gas, water distribution, and industrial processes, where temporary flow control is required for maintenance, repair, or modification activities. These fittings are available in different sizes and materials to accommodate pipeline specifications and operating conditions.

How Do Threaded Plug Line Stop Fittings Work?

- A hot tap is made on the pipeline to create a branch connection.

- The Threaded Plug Linestop Fitting is then threaded into this branch connection.

- Once securely in place, the fitting’s threaded plug is tightened to stop the product flow in the pipeline.

- Maintenance or repair work can then be performed downstream of the linestop point, while the rest of the pipeline remains operational.

- After the work is completed, the threaded plug is loosened, and the Threaded Plug Linestop Fitting is removed, restoring the pipeline’s flow.

What to Look for Before Buying Threaded Plug Linestop Fittings?

When buying Threaded Plug Linestop Fittings, several essential factors must be considered to ensure you select the right fittings for your specific application. Here are two key things to look for:

Material Compatibility: Ensure that the material of the Threaded Plug Linestop Fitting is compatible with the material of the pipeline it will be used with. Different materials have different chemical resistances and temperature tolerances, so it’s essential to choose fittings made from materials that can withstand the operating conditions of your pipeline without corroding or degrading over time.

Equip Up offers compactable Tecpesa branded Hot Tap Machines, Line stop Machines, Slim Valves, and power units, which are also compatible and interchangeable with TD Williamson Hot Tap Equipment.

Size and Pressure Rating: Select fittings for your pipeline that are the correct size and pressure rating. The fitting size should match the pipeline’s diameter, and the pressure rating should be sufficient to handle the maximum operating pressure of the pipeline system. Choosing fittings with the right size and pressure rating ensures a secure and reliable seal, minimizing the risk of leaks or failures during operation. It should be from our wide variety of fitting sizes and types.

These machines’ Tecpesa Hot tapping range is from 1/2” to 42”; they can also be used for Linestopping and installing threaded plugs. These Machines are available in three Boring Bar extensions: 18” for the TBL-182TH, 24” for the TBL-242TH, and 30” for the TBL302TH. All Machines are supplied complete with an operation and maintenance manual, ratchet crank handle for manual operation, and an optional air gun drive.

Apart from these, you must also consider factors such as thread type, sealing mechanism, and manufacturer reputation to ensure you get high-quality, reliable Threaded Plug Linestop Fittings that meet your specific requirements and performance expectations.