Safety is crucial when working with a line stop fitting due to the potential risks associated with pressurized piping systems and the procedures involved in line stopping operations. Here are some reasons why safety is important when working with line stop fitting:

- High Pressure: Piping systems often operate under high pressure, which can pose a significant risk of injury if not properly controlled and managed. Line stop fittings are used to temporarily stop the flow of fluid in a pressurized system, and any failure or mishandling can result in a sudden release of pressure, leading to serious injuries or damage to equipment.

- Hazardous Materials: Many industrial piping systems transport hazardous or toxic materials that can be harmful or even fatal if exposed to humans. Proper safety measures must be followed to prevent leaks, spills, or accidental releases of these substances during line stopping operations.

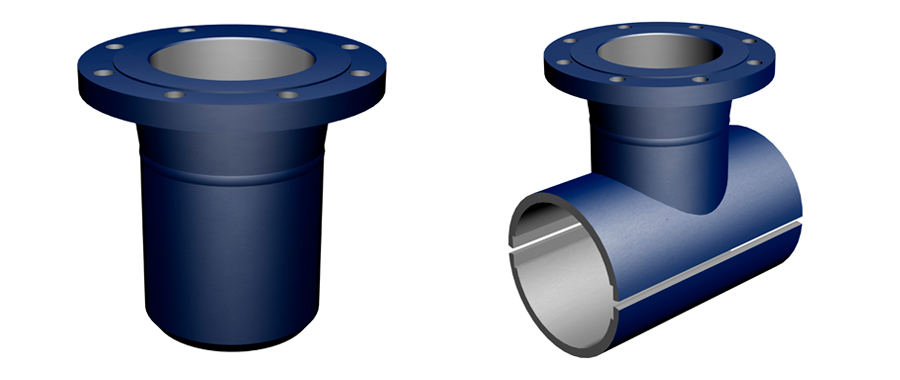

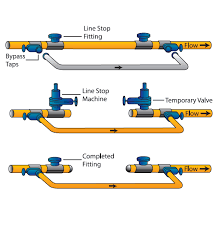

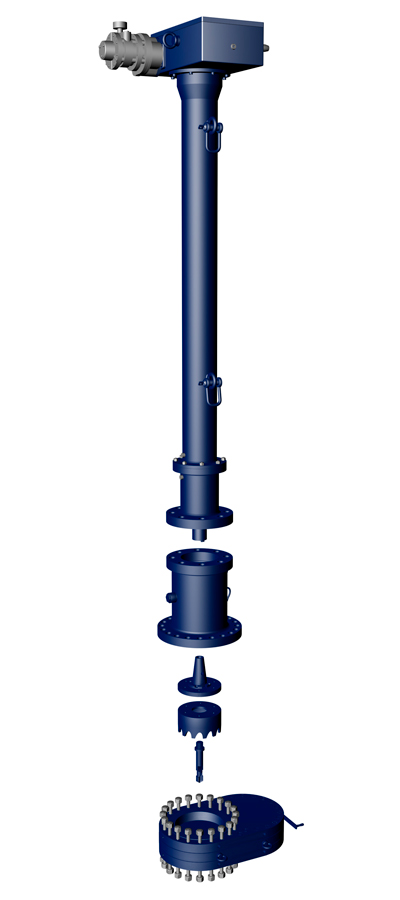

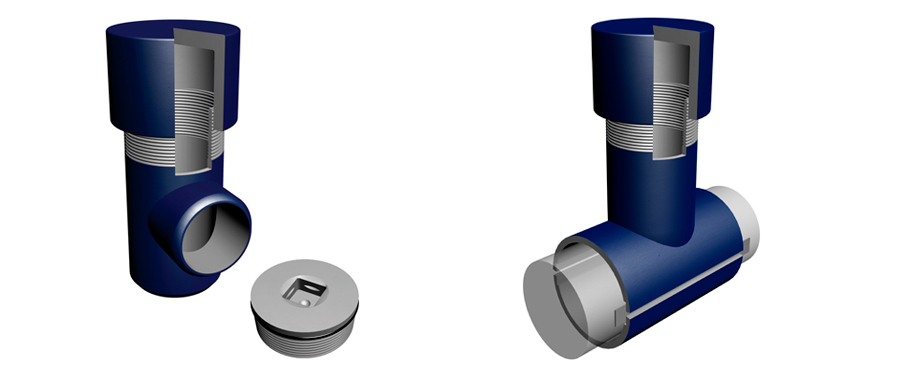

- Complex Procedures: Line stopping involves complex procedures, including cutting into live piping systems, installing line stop fittings, and performing the actual line stop. These operations require specialized knowledge, skills, and equipment to ensure they are carried out safely and effectively.

How to Ensure Safety When Buying a Hot Tap Line Stop

Ensuring safety when buying a hot tap line stop involves careful consideration of various factors to ensure the equipment’s quality, compatibility, and reliability. Here are some steps you can take to ensure safety when purchasing a hot tap line stop:

- Verify Product Specifications: Check the product specifications, including material composition, pressure and temperature ratings, and size compatibility to ensure the hot tap line stop is suitable for your specific application and meets the required safety standards.

- Consult with Experts: Seek advice from industry experts or consultants who specialize in hot tapping and line stopping operations. They can provide valuable insights and recommendations on selecting the right equipment and ensuring its safe and effective use.

- Check Safety Features: Ensure the hot tap line stop has built-in safety features, such as pressure relief valves, leak detection systems, and secure locking mechanisms, to prevent accidents and ensure the integrity of the piping system during line stopping operations.

The Codes to Follow When Buying a Line Stop Machine

The codes and standards governing a line stop machine can vary depending on the jurisdiction, industry, and specific application. However, some commonly referenced codes and standards in the United States include:

- ASME B31.3 – Process Piping: This code covers the design, fabrication, installation, and testing of process piping systems. It provides guidelines for materials, construction practices, and inspection requirements to ensure the integrity and safety of piping systems.

- API 570 – Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems: This code provides guidelines for the inspection, evaluation, and maintenance of in-service piping systems, including line stop machines used for hot tapping and line stopping operations.

- ANSI/ASME B16.5 – Pipe Flanges and Flanged Fittings: This standard covers the dimensions, materials, and pressure-temperature ratings of flanges and flanged fittings used in piping systems. It provides specifications for the design and installation of flanges, including those used in conjunction with line stop machines.

- OSHA Regulations: The Occupational Safety and Health Administration (OSHA) in the United States sets forth regulations and standards to ensure workplace safety. While OSHA does not specifically address line stop machines, it provides general guidelines for safe work practices, equipment safety, and hazard communication that apply to the use of line stop machines.

Buy the Right Line Stopper Fitting Online

If you are looking to buy line stopper fitting, then you need to get it from the right place. Log on to the online store of Equip Up and find the right tool for your piping project.