A reinforcement pad, also known as a Raised Face (RF) Pad, is used to strengthen a welded or fabricated pipe branch at the connection joints. Standard fittings are usually used to remove the branch from the runner or header pipe. However, these standard fittings are not affordable or readily available in a wider range of sizes. Depending on fabricated branch connections, they are not as hard-wearing as standard branch fittings. Therefore, pipe reinforcement pads are used to overcome this required strength.

They serve both purposes:

- Securing pipe links with vessels

- Reinforcing the structural integrity of pipe connections

A Detailed Overview of Reinforcing Pads

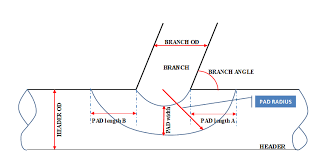

Reinforcing pads are an integral part of the industrial piping sector. They are also used in the petrochemical industry for vessel connections. Reinforcing pads come in the shape of doughnut-rolled plates. They are used in high-stress regions when a hole is made in the pipe to connect a secondary connection. These reinforcing pads ensure safety and reliability throughout the system. Repads are uniquely designed and their dimensions are precisely calculated to suit specific requirements. Pipe reinforcement pads are versatile, affordable, and precision-engineered, simplifying connections even when complex. Altogether, structural soundness is guaranteed throughout the system.

Where To Use Pipe Reinforcement Pads?

Standard Branch Fittings

- Challenge

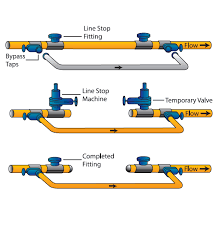

Depending on the operation, a branching pipe may be required from the main line. This additional connection is made by cutting a hole in the primary line, thereby creating a high-stress region at that particular spot. - Solution

A reinforcement pad plays a crucial role here, like a washer used to distribute the load of a threaded fastener. The joints in a “T” shape get reinforced as the plate effectively sits on the intersection or the point where the hole is made. This ensures the secured attachment of a branching pipe. Furthermore, it eliminates the need to install complex pipes like three-way pipe fittings.

Connection of Pipe to Vessel

- Challenge

Sometimes, pipes are required to connect to a vessel like containers or tanks, which presents many challenges. Much like the standard branch fitting, the vessel needs to be cut to make a hole. Quite naturally, this creates a high-stress region that often experiences various loads, pressures, and materials. - Solution

A Reinforced weld or RF Pad ensures a stable platform so the pipe can be welded to the vessel. The dimensions of the pads are only determined after proper engineering calculations to prevent leaks and accidents. The connection is accurately secured after calculating the exact dimension. The position of the weld is uniquely reinforced, and the stress is distributed. The reads are used to ensure structural integrity when it comes to Pipe-to-Vessel connections.

Features of a Reinforced Weld Pad

Pipe reinforcement pads can be customized according to the requirements. The pads feature a test port or weep hole. These ports vent trapped gases during the welding process and accommodate pressure gauges for leak testing. It is not necessary that these pads be available in a one-size-fits-all dimension. Based on the situation, fabricated Repads can also be used to enhance flexibility in installation and design.

You can avail top-grade reinforcing pads, pipe valves, and fittings from our online store at Equip Up. We are one of the leading providers of a wide range of industrial products, all of which are branded and certified. With years of experience, we can be your best source for high-performance industrial solutions.